Hand injuries from cutting are a common risk in many industrial workplaces, often happening in the blink of an eye. To avoid such accidents, choosing the right cut-resistant gloves is crucial. But have you ever wondered why these gloves are so tough to cut through? And how do you pick the perfect pair for your needs? Let’s break it down simply.

Why Are Cut-Resistant Gloves Hard to Cut Through? It’s All About the Yarn

The secret behind a cut-resistant glove’s toughness lies in its core yarn materials. These gloves are usually woven from coated yarns, with elastic fillers like nylon, polyester, or spandex added to make the glove core soft and flexible. The real protective power, though, comes from the coated yarns that determine the glove’s cut resistance level. Here are the most common high-performance materials used:

- Aramid Fiber: Boasts high strength, excellent wear resistance, and tear resistance. It also resists organic solvents, doesn’t conduct electricity, and is heat and flame-retardant.

- Steel Wire Fiber: Offers top-tier cut resistance and corrosion resistance, with long-lasting performance. The downside is that it’s heavier and stiffer than other materials.

- Basalt Fiber: A natural, eco-friendly option with inherent flame retardancy. It has strong cut and tear resistance, good wear resistance, acid-alkali resistance, and non-conductivity.

- Glass Fiber: Provides reliable cut resistance, fire resistance, water resistance, and insulation—at a relatively low cost.

- HPPE Fiber (High-Performance Polyethylene Fiber): Stands out for its ultra-high tensile strength, low density (making gloves lightweight), superior cut resistance, wear resistance, corrosion resistance, seawater resistance, UV resistance, aging resistance, impact resistance, and low-temperature resistance.

How to Spot a Quality Cut-Resistant Glove? Understand the EN388 Standard

Everpro Safety’s cut-resistant glove series is made of HPPE fiber and certified to the EU EN388 standard, reaching a Level 5 cut resistance—ideal for high-risk work scenarios. But what exactly is the EN388 standard, and how do you read its labels?

What Is the EN388 Standard?

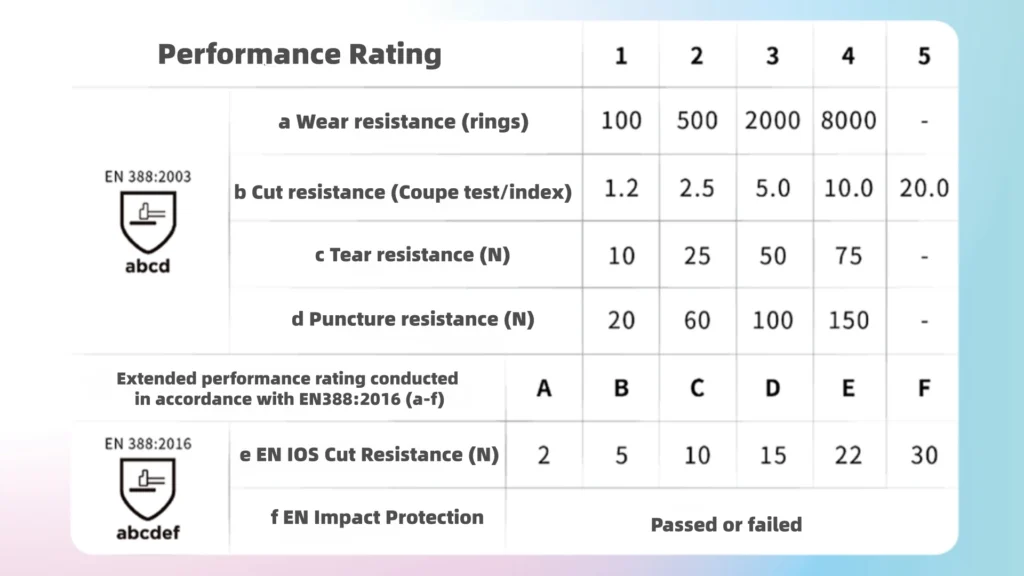

EN388 is a key European safety standard that evaluates the performance of gloves designed to protect against mechanical risks. The latest version is EN388:2016+A1:2018, revised and released in December 2018 based on the 2016 edition. It’s widely recognized globally as a benchmark for glove safety.

Why Does Understanding EN388 Matter?

The EN388 standard tests gloves on four core performance metrics: cut resistance, abrasion resistance, tear resistance, and puncture resistance. Knowing how to interpret its labels helps you:

- Confirm if a glove provides sufficient protection for your work environment.

- Choose the most suitable product by comparing data across all four metrics, ensuring long-term safety in hazardous settings.

How to Read EN388 Labels? Decode the A-F Markings

The EN388 label uses letters (A-F) and numbers to show a glove’s performance. Here’s what each position means:

| Letter | Performance Metric | Rating Scale | Explanation |

|---|---|---|---|

| A | Abrasion Resistance | 1–4 | Higher numbers mean better resistance to wear and tear |

| B | Cut Resistance (COUPE Test) | 1–5 | Level 5 is the highest rating for this test method |

| C | Tear Resistance | 1–4 | Higher numbers mean the glove resists tearing better |

| D | Puncture Resistance | 1–5 | Higher numbers mean stronger protection against sharp object punctures |

Extended Performance Ratings in EN388:2016(a-f)

The updated standard also includes two additional key indicators:

- E: Cut Resistance (EN ISO Test). This is a mandatory benchmark for cut protection, rated from A (lowest) to F (highest). An F rating means the glove has the strongest cut resistance available.

- F: Impact Protection. If a glove passes the impact resistance test, it will be marked with P. If there’s no marking, the glove either failed the test or impact protection isn’t applicable to it.

Critical Warning: Wearing the Wrong Gloves Is More Dangerous Than Wearing None

In the workplace, hands face multiple risks every day. Wearing ill-suited gloves can give workers a false sense of security, making them overlook potential hazards. For example, using a low-protection glove in a high-risk cutting environment can lead to severe injuries. Always check for the EN388:2016+A1:2018 certification—it’s your guarantee of safety.

Note: EN388 applies to all protective gloves designed to prevent physical and mechanical injuries caused by abrasion, cutting, puncture, tearing, etc.

How to Choose Cut-Resistant Gloves for Different Scenarios? Everpro Safety Level 5 Recommendations

Everpro Safety’s Level 5 cut-resistant gloves are certified to EN388 standards and come in three practical styles to meet diverse workplace needs:

- Lightweight, flexible, and highly breathable, these gloves offer top-tier Level 5 cut protection without sacrificing dexterity. Perfect for daily maintenance and parts assembly work, they let you handle small components with ease while keeping your hands safe.

2. HPPE + Nitrile Frosted Coated Level 5 Cut-Resistant Gloves (EN388 Level 5)

- Made with HPPE fiber and a nitrile frosted coating, these gloves deliver Level 5 cut resistance, plus excellent slip resistance and oil resistance. They’re comfortable to wear and ideal for handling sharp parts and materials.

3. Reinforced Thumb Crotch Nitrile Frosted Level 5 Cut-Resistant Gloves (EN388 Level 5)

- Built with HPPE fiber and nitrile frosted coating, these gloves feature a reinforced thumb crotch design—a high-wear area—to boost abrasion and cut resistance. With an ergonomic fit, they’re breathable, comfortable, and flexible, making them a great choice for heavy machinery operation, glass/metal processing, and other high-cut-risk scenarios.

What Makes Everpro Safety Cut-Resistant Gloves Stand Out?

- Upgraded Wear-Resistant Technology: All-around grip and flexible operation, so you can handle both precision instruments and heavy equipment with confidence.

- Advanced Cut-Resistant Yarn Technology: Tough and reliable protection to take on any cutting challenge.

- 13-Gauge Knitting & Ergonomic Design: Combined with nitrile frosted coating, these gloves enhance wear resistance, slip resistance, and breathability—keeping your hands comfortable even during long hours of high-intensity work.

- Reinforced Thumb Crotch Detail: A focus on quality that targets the most vulnerable part of the glove, combining HPPE, nitrile frosted, and PU materials for maximum protection and comfort.

- Professional EN388 Certification: Rigorously tested to meet high safety standards, Everpro Safety gloves prioritize both your health and safety in every task.